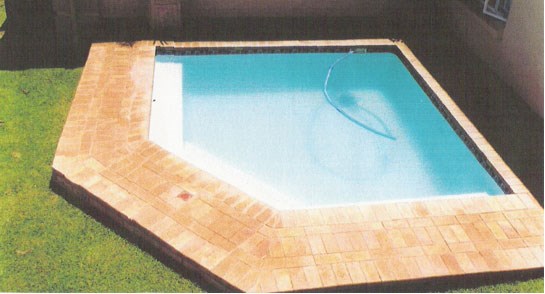

Information about pre-moulded pool:

As a wholly factory manufactured moulded fibreglass pool, it is often said “ What you see is what you get”. This is only partially the truth.

What you see on the inside is the blue interior colour of the pool and a black finishing “paint” on the outside of the pool. Most finished pre-moulded pool shells “looks” the same from the outside.

What matters is what is in between those two layers, as that will determine the strength and longevity of a pre-moulded fibreglass pool.

The NSPI of SA (National Spa and Pool Institute of South Africa) prescribes minimum standards for the manufacturing of pre-moulded fibreglass pools.

In line with the NSPI standards, Blue Lagoon Pools only install pools that are manufactures as follows:

FIRST PROCESS

Extremely durable K-75 colour layer that comes in contact with water

SECOND PROCESS

A K-75 layer is applied for protection against chemically enriched pool water

THIRD PROCESS

K-75 resin and layers of chopped strand and roving matting are laminated in layers to create the structure and support ribs of the pre-moulded shell. Thickness varies from 6mm to 16mm depending on the size and application of the pool.

FORTH PROCESS

K-50 Layer to protect the pool against alkaline attacks from the surrounding soil.